We completed this project for a technology and services provider to the oil and gas industry from upstream to end-user downstream. The company’s services encompass several services, from exploration, drilling, and production to refining, processing, and distribution.

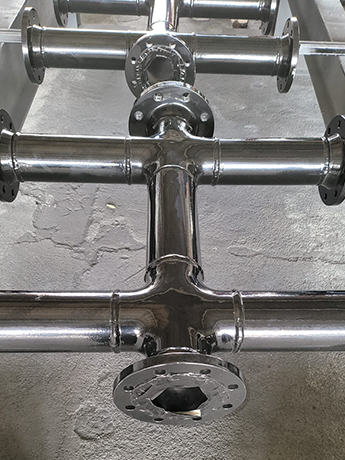

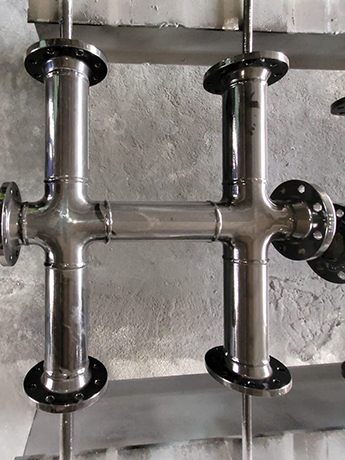

Oil and gas manifold diverts oil or gas, without flow interruption, from the separator to a crude oil burner for disposal, to a surge tank or gauge tank for measurements or storage, or to a production line. Oil and gas manifolds also isolate the test equipment to prevent flow interruptions if the testing equipment is pulled out of service temporarily. MAXON CRS was first applied to prevent corrosion formation, and also to reinforce the manifolds. MAXON H2Poxy-A was then applied as a liquid-resistant, protective layer for the manifolds. The combination ensures that the pipe would not corrode despite being subject to oil, gas, water, high temperatures, and harsh climate.

Our products are GREENGUARD UL2818 GOLD Certified.

Our products are made of water-based materials and hence there is no explosive danger.

Our products, for example, the MAXON-CRS, can be applied even in 100% humidity.

Our products are simple and easy to apply, without the need for any kind of sandblasting.

Reduced application time compared to other products and it increases the intervals for maintenance cycle periods.

Products can be applied during the operation of the to-be treated equipment.

Eco-friendly products and contains very low VOC levels.

You don’t lose any unused material, you can store it and it won’t lose any of its properties.

Reduce costs – between 75%-85% savings in labour costs.

Eco-friendly products and contains very low VOC levels.

Click the button to connect with us.