Product Brochure

Product BrochureC2M stands for Cement to Metal Bond. C2M is a cement-based, cost-effective, multi-functional coating that functions as a protective layer that can be used as part of a more comprehensive anti-corrosion coating system. C2M dries smooth, creating a strong bridge between rusted metal surfaces and application-specific topcoats.

C2M requires minimal hard rust surface preparation while providing high substrate and topcoat bond strength. It also cleans up easily and quickly with just water and is environmentally friendly and safe. Highly flexible, it can be bent up to 90 degrees without cracking.

Maxon C2M stands out as an environmentally friendly product as it incorporates recycled industrial material, boasts an exceptionally low VOC level of less than 20g per liter, and offers effortless application and use.

Result of our work on an oil rig project. The project required sand-blasting or hand tooling, but the location of the deck made it cost-prohibitive. Our products, CRS and C2M, don’t require any blasting or hand tooling. CRS was applied. When dry, a topcoat of C2M was applied.

Maxon’s CRS and C2M proved advantageous for this project as it does need sandblasting or grinding off the existing rust. These products can be applied after a power wash and degreasing of the surface to remove any particles and was completed within three days with three workmen.

We used C2M as the product for cleaning the flooring. With remarkable results, the VCT was fully revamped and given a fresh new look.

Maxon C2M was chosen as the apt solution for this repair project with its incredible capacity to resist multiple environmental threats, including ultraviolet light, abrasion, freeze/thaw, thermal shock, salt, fog, and humidity. The transformation was incredible, as the difference between the former and the latter is clearly evident to all.

Working as a system, Maxon products will act as a penetrant and a barrier to solving this widespread problem. Each step uses waterborne products that are easy to apply. Cure times are minimal, and the products are safe for the applicators and safe for the environment.

A repair project on bins that showed extensive corrosion damage due to exposure to salts and moisture. It required only minimal prep work without grinding or blasting. CRS coating was given on all edges first for maximum protection and was applied via an airless sprayer. Once cured, topcoat paint was applied.

A very light application of CRS is used along with C2M for increased durability. Our special epoxy, containing Kevlar fibres and ceramic microspheres in Safety Yellow is used to cover the entire bollard to provide extreme resistance to abrasion, ensuring years of trouble-free service. VLS was also used to loosen the bolts to remove the bollard, removing the need to cut or weld new mounting.

We achieved dramatic results with Maxon CRS and C2M. With its remarkable capability to penetrate tightly adhered intact rust, Maxon solutions pacify the corrosion process, dramatically reducing prep time and costs.

In spite of extreme pitting, shedding, and biological corrosion, all the prep work was accomplished through pressure washing and de-greasing. The project was completed under budget due to the application process’ simple learning curve. Material usage lessened during the length of the job as the crew got more experienced.

CRS was applied directly onto the rust on the surface without the need for sandblasting or grinding. With the amazing ability to penetrate tightly adhered intact rust and pacify the corrosion process along with its oxygen blocking properties, corrosion can be stopped in its track.

The application of MAXON CRS ensured that existing rust was eradicated and the occurrence of future corrosion was close to none. MAXON C2M was then applied to strengthen the bond and provide a layer over which MAXON H2POXY-A could be applied; this made the structure further resistant to the harsh environment and liquid spills.

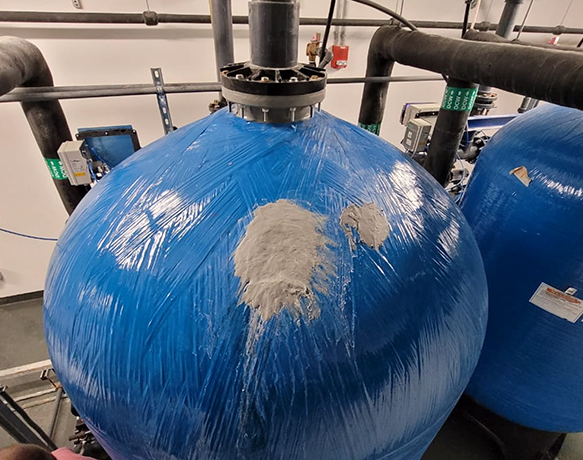

We applied C2M to seal the crack and to fortify the structure and prevent any future incidents. The tanks were then coated with MAXON H2POXY-A, hence forming a water-resistant barrier.

The powerful combination of MAXON C2M, H2POXY-A, CRS, and VLS has highly competitive qualities and allows for easier, greener, minimally disruptive and economically viable maintenance of metals and concrete. The results are evident and it also provides protection against future corrosion.

Explore our wide range of solutions for the oil and gas industry and the many projects we have undertaken globally within the sector.

Solutions for the Energy sector and the wide variety of projects we have undertaken in the sector, worldwide.

Solutions for the Manufacturing sector and also about the projects we have completed for this vertical, across geographies.

With a wide variety of solutions for the Productions sector, we have been able to provide innovative and pathbreaking answers for several projects.

Explore the wide range of anti-corrosion solutions for the Fabrication sector and gain an understanding of the projects we have successfully completed in this industry vertical.

Anti-corrosion solutions that are tailored for defence organisations for the prevention of corrosion in vehicles, aircraft, equipment, infrastructure, facilities, naval vessels and more.

Maxon's corrosion protection solutions safeguard against losses and complaints due to metal deterioration caused by natural elements and general wear and tear.

A wide range of corrosion protection solutions for the Mining sector to ensure maximum production and profit along with continued growth.

Explore the wide range of anti-corrosion solutions for the Construction industry and get an overview of the projects we have successfully completed for this industry segment.

Discover a vast array of anti-corrosion solutions for the Public Works sector and all the projects we have undertaken in the Public Works sector.

Learn about our extensive expertise in the Marine industry and discover our range of world-class products designed to protect Marine assets.

We were asked to do the restorative work on three old but constantly used docks. The operation was tough as the docks had to be operational in between the restoration process. We were able to work out a plan and complete the restoration for three similar docks.

VIEW PROJECT

Our products are GREENGUARD UL2818 GOLD Certified.

Our products are made of water-based materials and hence there is no explosive danger.

Our products, for example, the MAXON-CRS, can be applied even in 100% humidity.

Our products are simple and easy to apply, without the need for any kind of sandblasting.

Reduced application time compared to other products and it increases the intervals for maintenance cycle periods.

Products can be applied during the operation of the to-be treated equipment.

Eco-friendly products and contains very low VOC levels.

You don’t lose any unused material, you can store it and it won’t lose any of its properties.

Reduce costs – between 75%-85% savings in labour costs.

Eco-friendly products and contains very low VOC levels.

Click the button to connect with us.