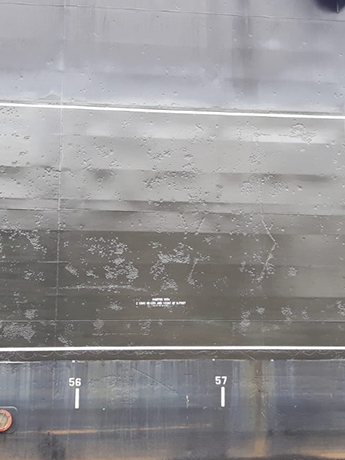

This project involved floating docks that were old, second hand and constantly in use. As they get rented out for amounts, the docks needed to be operational in between the restoration. Hence, the restoration was done as a piecemeal operation. This meant having to dismantle the gear for the dock to be used and then return to do the next section after a few days. This situation required us to start setting up all over again. There were 3 similar docks and these docks are approximately 300 m long, 15 m high and 50 m wide.

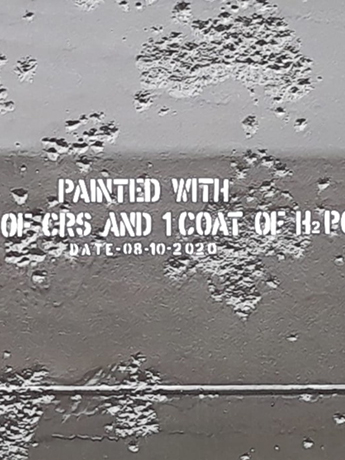

This is the result of our restorative work using CRS and H2POXY-A. We were able to achieve coverage of approx. 250 m2 - 300 m2 per hour and we needed about 180 gallons of CRS and 400 H2POXY kits +/-

Our products are GREENGUARD UL2818 GOLD Certified.

Our products are made of water-based materials and hence there is no explosive danger.

Our products, for example, the MAXON-CRS, can be applied even in 100% humidity.

Our products are simple and easy to apply, without the need for any kind of sandblasting.

Reduced application time compared to other products and it increases the intervals for maintenance cycle periods.

Products can be applied during the operation of the to-be treated equipment.

Eco-friendly products and contains very low VOC levels.

You don’t lose any unused material, you can store it and it won’t lose any of its properties.

Reduce costs – between 75%-85% savings in labour costs.

Eco-friendly products and contains very low VOC levels.

Click the button to connect with us.