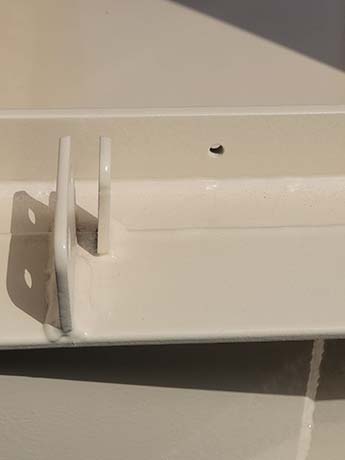

This project was for the defence forces. Used as a mobile pump for filling fuel in vehicles, aircraft and remote areas otherwise inaccessible to regular refuelling methods, fuel skid containers play a vital role as it is a readily available supply of fuel. But due to exposure to the harsh environment, the fuel skid container started showing signs of corrosion.

Applying MAXON CRS ensured that existing rust was eradicated and the occurrence of future corrosion was close to none. MAXON C2M was then applied to strengthen the bond and provide a layer over which MAXON H2POXY-A could be applied. This made the structure further resistant to the harsh environment and liquid spills.

The application MAXON CRS ensured that existing rust was eradicated and the occurrence of future corrosion was close to none. MAXON C2M was then applied to strengthen the bond and provide a layer over which MAXON H2POXY-A could be applied. This made the structure further resistant to the harsh environment and liquid spills.

Our products are GREENGUARD UL2818 GOLD Certified.

Our products are made of water-based materials and hence there is no explosive danger.

Our products, for example, the MAXON-CRS, can be applied even in 100% humidity.

Our products are simple and easy to apply, without the need for any kind of sandblasting.

Reduced application time compared to other products and it increases the intervals for maintenance cycle periods.

Products can be applied during the operation of the to-be treated equipment.

Eco-friendly products and contains very low VOC levels.

You don’t lose any unused material, you can store it and it won’t lose any of its properties.

Reduce costs – between 75%-85% savings in labour costs.

Eco-friendly products and contains very low VOC levels.

Click the button to connect with us.